Always Ready to Help

AccroSeal® provides quality custom machined parts and top-of-the-line grease products whenever needed.

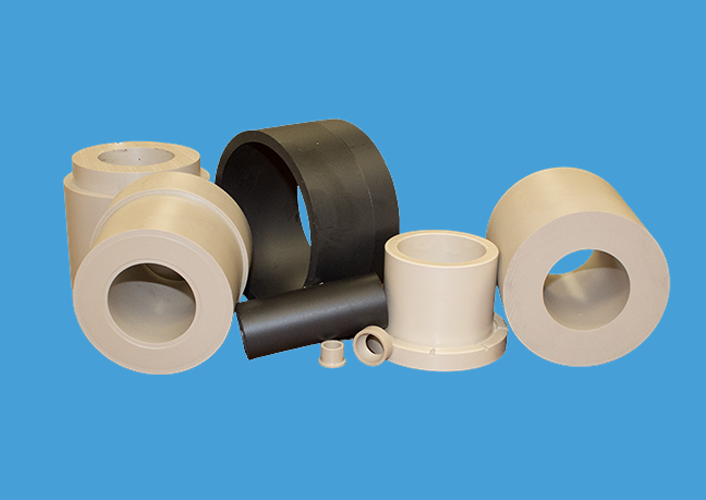

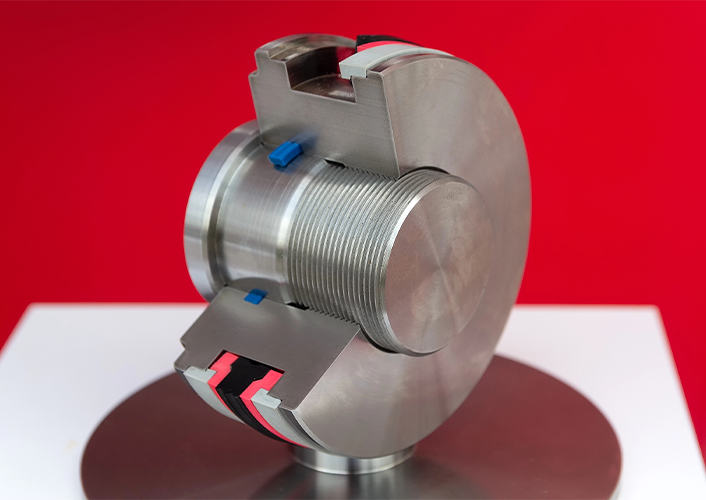

AccroSeal specializes in the production of PEEK (Polyether Ether Ketone) seals, engineered for demanding environments where standard polymers fall short. Known for their outstanding mechanical strength, chemical resistance, and thermal stability, PEEK seals are ideal for high-pressure, high-temperature, and high-load applications across critical industries.

We manufacture precision-machined PEEK seals in custom profiles, with tight tolerances and fast lead times. Our team partners closely with customers to ensure every seal meets the exact mechanical, thermal, and chemical requirements of your application.