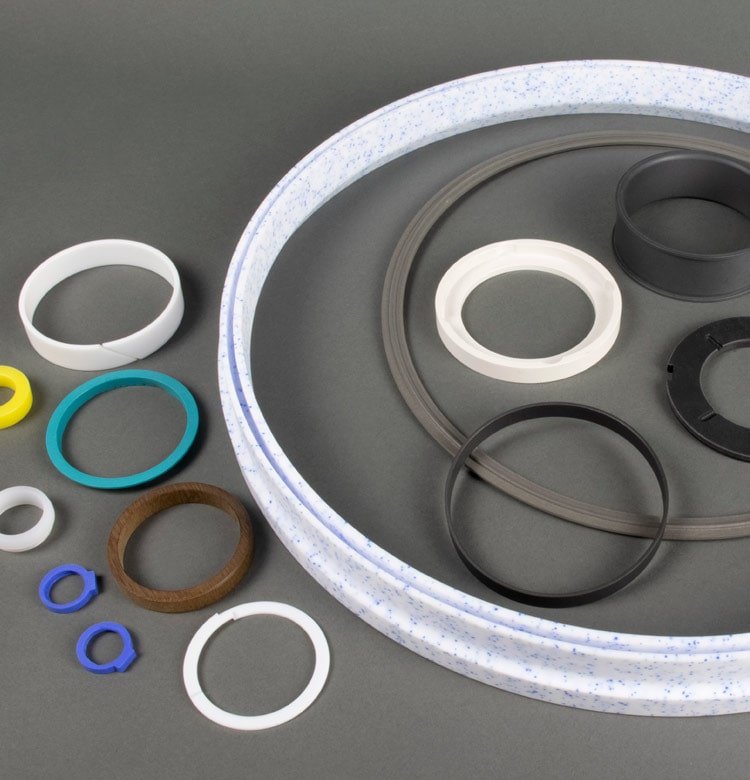

Energized Seals

Spring-Powered Protection

Energized Seals are sealing devices consisting of a PTFE or other polymer seal jacket, energized by a corrosion resistant metal spring or elastomer. When the seal is seated in the gland, a spring is under compression, applying force on the gland sealing surfaces, thereby creating a tight barrier to prevent gas or fluids from leaking.

The spring also provides resiliency to compensate for seal wear, gland misalignment, or eccentricity. While spring force provides adequate force for sealing at low pressure, at high pressure the system pressure augments the spring force to provide an even tighter seal. Accrolon® seals are precision machined from PTFE and other high performance polymers.

AccroSeal partners with the premier spring manufacturers in the U.S. to provide a duo of engineering specialties. Our ability to custom manufacture the seal jacket to customer specifications, coupled with our spring partners, provides a service you won’t find anywhere else.